Implementation of Total Quality Management (TQM): Toyota Case Study

- To find inspiration for your paper and overcome writer’s block

- As a source of information (ensure proper referencing)

- As a template for you assignment

Introduction

Implementation of tqm in toyota, tqm practices in toyota, benefits of tqm in toyota, examples of tqm in toyota, toyota quality management, toyota tqm implementation challenges.

The Toyota Corporation case study report is based on the implementation of total quality management (TQM) meant to improve the overall performance and operations of this automobile company. TQM involves the application of quality management standards to all elements of the business.

It requires that quality management standards be applied in all branches and at all levels of the organization. The characteristic of Toyota Corporation going through the total quality process is unambiguous and clear.

Toyota has limited interdepartmental barriers, excellent customer and supplier relations, spares time to be spent on training, and the recognition that quality is realized through offering excellent products as well as the quality of the entire firm, including personnel, finance, sales, and other functions.

The top management at Toyota Corporation has the responsibility for quality rather than the employees, and it is their role to provide commitment, support, and leadership to the human and technical processes (Kanji & Asher, 1996).

Whereas the TQM initiative is to succeed, the management has to foster the participation of Toyota Corporation workers in quality improvement and create a quality culture by altering attitudes and perceptions towards quality.

This research report assesses the implementation of TQM and how Toyota manages quality in all organization management systems while focusing on manufacturing quality. The report evaluates the organization management elements required when implementing TQM, identifies, and investigates the challenges facing Quality Managers or Executives in implementing Quality Management Systems.

In order to implement TQM, Toyota corporations focused on the following phases:

- The company extended the management responsibility past the instantaneous services and products

- Toyota examined how consumers applied the products generated, and this enabled the company to develop and improve its commodities

- Toyota focused on the insubstantial impacts on the procedures as well as how such effects could be minimized through optimization

- Toyota focused on the kaizen (incessant process development) in order to ensure that all procedures are measurable, repeatable, and visible.

The commitment from business executives is one of the key TQM implementation principles that make an organization successful. In fact, the organizational commitment present in the senior organizational staff ranges from top to lower administration. These occur through self-driven motives, motivation, and employee empowerment. Total Quality Management becomes achievable at Toyota by setting up the mission and vision statements, objectives, and organizational goals.

In addition, the TQM is achievable via the course of active participation in organizational follow-up actions. These actions denote the entire activities needed and involved during the implementation of the set-out ideologies of the organization. From Toyota Corporation’s report, TQM has been successful through the commitment of executive management and the organizational workforce (Toyota Motor Corporation, 2012).

Through inventory and half the bottlenecks at half cost and time, the adopters of TMS (Toyota Management System) are authorized to manufacture twice above the normal production. To manage the quality in all organizational management systems, the Toyota Production System incorporates different modernisms like strategy or Hoshin Kanri use, overall value supervision, and just-in-time assembly.

The amalgamation of these innovations enables Toyota to have a strong competitive advantage despite the fact that Toyota never originated from all of them. The 1914 Henry Ford invention relied on the just-in-time production model. The Ford system of production, from a grand perspective, warrants massive production, thus quality (Toyota Motor Corporation, 2012).

Kanji and Asher (1996) claim that to manage the minute set of production necessitated by the splintered and small post-war marketplaces, the JIT system focuses on the motion and elimination of waste materials. This reduces crave for work-in-process inventory by wrapping up the long production lines. Toyota Corp wraps the production lines into slashed change-over times, a multi-trained workforce that runs manifold machines, and new-fangled cells into a U shape.

When supplementing the just-in-cells, the system of kanban is employed by the Toyota Corporation to connect the cells that are unable to integrate physically. Equally, the system helps Toyota integrate with other external companies, consumers, and suppliers.

The TQM and the creativity of Toyota proprietors both support the quality at the source. The rectification and discovery of the production problems require the executives to be committed. At the forefront of Toyota operations, the managers integrate a number of forms of operational quality checks to ensure quality management at all levels.

The uninterrupted tests help the Toyota workforce engaging in the assembly course to scrutinize the value of apparatus, implements, and resources utilized in fabrication. The checks help in the scrutiny of the previously performed tasks by other workers. However, the corporation’s own test enables the workers to revise their personal advances in the assembly course.

The Toyota process owners set up the mistake-proofing (Poka-yoke) procedures and devices to capture the awareness of management and involuntarily correct and surface the augmenting problems. This is essential for the critical production circumstances and steps that prove impractical and tricky for Toyota employees to inspect.

Nevertheless, the policy deployment system decentralizes the process of decision-making at Toyota. This context of implementing Total Quality Management originates from Hoshin Kanri’s management by objective (MBO).

This aspect becomes more advantageous to Toyota when dealing with quality management. The system initially puts into practice the coordinated approach and provides a clear structure for the suppliers, producers, and consumers through inter-organizational cost administration. Moreover, Toyota executives can solve the concurrent delivery, cost, and quality bottlenecks, thus replacing and increasing the relatively slow accounting management mechanisms.

Customer focus that leads to the desired customer satisfaction at Toyota Company is one of the major success factors in TQM implementation. For every business to grow, it should have understanding, reliable, and trustworthy customers. The principle of customer satisfaction and focus has been the most presently well-thought-out aspect of Toyota’s manufacturing quality.

The TQM may characteristically involve total business focus towards meeting and exceeding customers’ expectations and requirements by considering their personal interests. The mission of improving and achieving customer satisfaction ought to stream from customer focus.

Thus, when focusing on manufacturing quality, this aspect enhances TQM implementation. The first priorities at Toyota are community satisfaction, employees, owners, consumers, and mission. The diverse consumer-related features from liberty. The concern to care is eminent in Toyota Corporation during manufacturing.

Toyota has three basic perspectives of TQM that are customer-oriented. These are based on its manufacturing process traced back to the 1950s. The strategies towards achieving quality manufacturing, planning, and having a culture towards quality accomplishment are paramount for TQM implementation to remain successful. To enhance and maintain quality through strategic planning schemes, all managers and employers must remain effectively driven.

This involves training workers on principles concerning quality culture and achievement. Scheduling and planning are analytical applications at Toyota Company that purposes in assessing customer demand, material availability, and plant capacity during manufacturing.

The Toyota Corporation has considerable approaches that rank it among the successful and renowned implementers of TQM. From the inherent and designed structure of Toyota, it becomes feasible to comprehend why quality manufacturing is gradually becoming effective. The inspection department is responsible for taking corrective measures, salvaging, and sorting the desired manufactured product or service quality.

The Toyota Corporation also has a quality control system that is involved in determining quality policies, reviewing statistics, and establishing quality manuals or presentation data. Furthermore, quality assurance is one of the integral principles in quality implementation that is practically present at Toyota. The quality assurance and quality inspectors throughout the Toyota Company structure also manage research and development concerning the quality of manufactured products and services.

The Toyota production and operations management system is similarly dubbed as the managerial system. In fact, in this corporation, operational management is also referred to as the production process, production management, or operations (Chary, 2009). These simply incorporate the actual production and delivery of products.

The managerial system involves product design and the associated product process, planning and implementing production, as well as acquiring and organizing resources. With this broad scope, the production and operation managers have a fundamental role to play in the company’s ability to reach the TQM implementation goals and objectives.

The Toyota Corporation operations managers are required to be conversant and familiar with the TQM implementation concepts and issues that surround this functional area. Toyota’s operation management system is focused on fulfilling the requirements of the customers.

The corporation realizes this by offering loyal and express commodities at logical fees and assisting dealers in progressing commodities proffered. As Slack et al. (2009) observed, the basic performance objectives, which pertain to all the Toyota’s operations, include quality, speed, flexibility, dependability, and cost. Toyota Company has been successful in meeting these objectives through its production and operation functions.

Over several decades, Toyota’s operational processes and management systems were streamlined, resulting in the popularly known Toyota Production System. Although the system had been extensively researched, many companies, such as Nissan, experienced difficulties in replicating TPS.

The TPS was conceived when the company realized that producing massive quantities from limited product lines and ensuring large components to achieve maximum economies of scale led to flaws. Its major objectives were to reduce cost, eliminate waste, and respond to the changing needs of the customers. The initial feature of this system was set-up time reduction, and this forms the basis of TQM implementation.

At Toyota Corporation, quality is considered as acting responsibly through the provision of blunder-gratis products that please the target clientele. Toyota vehicles are among the leading brands in customer satisfaction. Due to good quality, its success has kept growing, and in 2012, the company was the best worldwide. Moreover, Toyota has been keen on producing quality vehicles via the utilization of various technologies that improve the performance of the vehicles.

While implementing TQM, Toyota perceives speed as a key element. In this case, speed objective means doing things fast in order to reduce the time spent between ordering and availing the product to the customer.

The TPS method during processing concentrates on reducing intricacy via the use of minute and uncomplicated machinery that is elastic and full-bodied. The company’s human resources and managers are fond of reorganizing streams and designs to promote minimalism. This enhances the speed of production.

Another objective during TQM implementation is dependability. This means timely working to ensure that customers get their products within the promised time. Toyota has included a just-in-time production system comprised of multi-skilled employees who work in teams. The kanban control allows the workers to deliver goods and services as promised. Advancing value and effectiveness appears to be the distress for administrators, mechanical specialists, and other Toyota human resources.

During TQM implementation, Toyota responds to the demands by changing its products and the way of doing business. Chary (2009) argues that while implementing TQM, organizations must learn to like change and develop responsive and flexible organizations to deal with the changing business environment.

Within Toyota plants, this incorporates the ability to adopt the manufacturing resources to develop new models. The company is able to attain an elevated degree of suppleness, manufacturing fairly tiny bunches of products devoid of losses in excellence or output.

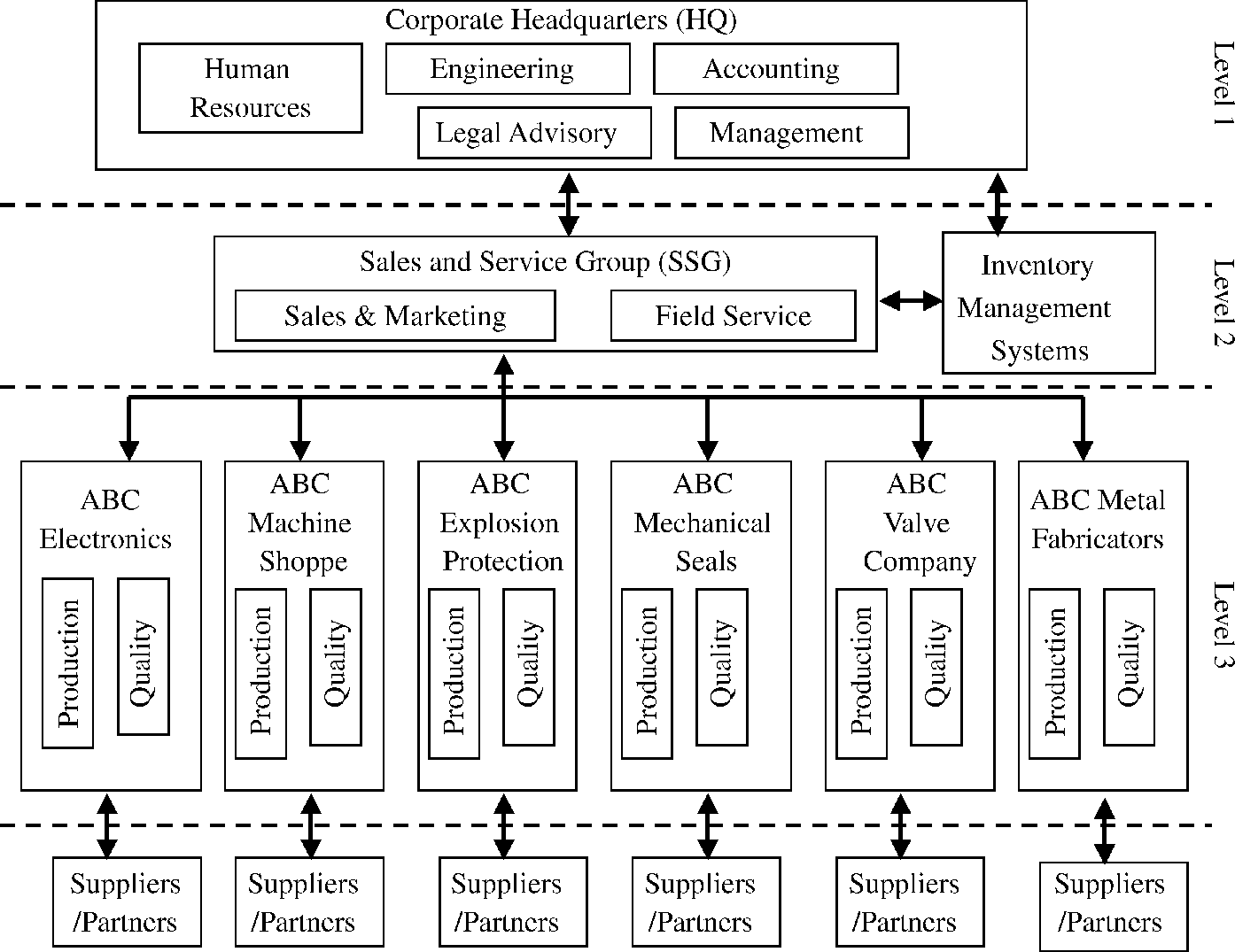

The organizational hierarchy and job descriptions also determine the successful implementation of the TQM. Toyota is amongst the few companies whose organizational structure and task allocation have proved viable in TQM implementation. The company has three levels of management. See the diagram below.

Management hierarchy

Despite the hierarchy and task specification, employees are able to make independent decisions and take corrective measures when necessary to ensure quality during production. Team working is highly encouraged at Toyota Corporation, and this plays a significant role during TQM implementation. All stakeholders are incorporated in quality control initiatives to ensure client demands are satisfied.

However, all employees are required to carry out their assigned tasks, and the management closely supervises the ways of interactions between workers. The management ensures that the manufacturing lines are well-built and all employees are motivated to learn how to improve the production processes.

Toyota is among the few manufacturers in the complete automobile industry that consistently profited during the oil crisis in 1974. The discovery was the unique team working of the Japanese that utilized scientific management rules (Huczynski & Buchanan, 2007).

The joint effort in Japan, usually dubbed Toyotaism, is a kind of job association emphasizing ‘lean-assembly.’ The technique merges just-in-time production, dilemma-answering groups, job equivalence, authoritative foremost-streak administration, and continued procedure perfection.

Just-in-time (JIT) assembly scheme attempts to accomplish all clients’ needs instantly, devoid of misuse but with ideal excellence. JIT appears to be dissimilar from the conventional functional performances in that it emphasizes speedy production and ravage purging that adds to stumpy supply.

Control and planning of many JIT approaches are concerned directly with pull scheduling, leveled scheduling, kanban control, synchronization of flow, and mixed-model scheduling (Slack et al., 2009).

Toyota appears to be amongst the principal participants in changing Japan to a kingpin in car production. Companies, which have adopted the company’s production system, have increased efficiency and productivity. The 2009 industrial survey of manufacturers indicates that many world-class firms have adopted continuous-flow or just-in-time production and many techniques Toyota has been developing many years ago.

In addition, the manufacturing examination of top plant victors illustrates that the mainstream them utilize lean production techniques widely. Thus, team-working TPS assists Toyota Corporation in the implementation of TQM.

Executives and Quality Managers face some challenges while implementing Quality Management Systems in organizations. In fact, with a lack of the implementation resources such as monetary and human resources in any organization, the implementation of TQM cannot be successful. Towards the implementation of programs and projects in organizations, financial and human resources have become the pillar stones.

The approach of TQM impels marketplace competence from all kinds of organizational proceeds to ensure profitability and productivity. To meet the desired results in TQM implementation, an organization ought to consider the availability of human and financial resources that are very important for the provision of an appropriate milieu for accomplishing organizational objectives.

In the case of Toyota, which originated and perfected the philosophy of TQM, the Executives, and Quality Managers met some intertwined problems during TQM implementation. The flaw in the new product development is increasingly becoming complicated for the managers to break and accelerate, thus creating reliability problems. Besides, secretive culture and dysfunctional organizational structure cause barriers in communication between the top management, thus, in turn, augmenting public outrage.

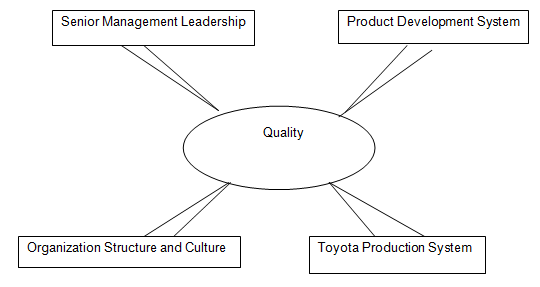

The top executives may fail to provide and scale up adequate training to the suppliers and new workforces. As a result, cracks are created in the rigorous TPS system. In addition, a lack of leadership at the top management might cause challenges in the implementation of TQM. Therefore, in designing the organizational structures and systems that impact quality, the senior executives and managers must be responsible, as elaborated in Figure 2 below.

Total Quality Management is a concept applied in the automobile industry, including the Toyota Corporation. It focuses on continuous improvement across all branches and levels of an organization. Being part of Toyota, the concept defines the way in which the organization can create value for its customers and other stakeholders. Through TQM, Toyota Corporation has been able to create value, which eventually leads to operation efficiencies.

These efficiencies have particularly been achieved by continuous correction of deficiencies identified in the process. A particular interest is the central role that information flow and management have played in enabling TQM initiatives to be implemented, especially through continuous learning and team working culture.

The Toyota way (kaizen), which aims at integrating the workforce suggestions while eliminating overproduction and manufacturing wastes, helps the company to respect all the stakeholders and give clients first priority. The objectives are realized through TPS.

Chary, D. 2009, Production and operations management , Tata McGraw-Hill Education Press, Mumbai.

Huczynski, A. & Buchanan, D. 2007, Organizational behavior; an introductory text, Prentice Hall, New York, NY.

Kanji, G. K. & Asher, M. 1996, 100 methods for total quality management , SAGE Thousands Oak, CA.

Slack, N. et al. 2009, Operations and process management: principles and practice for strategic management, Prentice Hall, New York, NY.

Toyota Motor Corporation 2012, Annual report 2012. Web.

- Google Corporation Investments Evaluation

- How HR Approaches Match Up With the Strategic Initiatives

- Lean Manufacturing: Processes

- Toyota Motor Corporation's Sustainability

- Just-in-Time Techniques, Their Upsides and Downsides

- Barriers and Facilitators of Workplace Learning

- The Science of Behavior in Business

- Standards, models, and quality: Management

- Managerial and Professional Development: Crowe Horwath CPA limited

- Managerial and Professional Development: Deloitte & Touché Company

- Chicago (A-D)

- Chicago (N-B)

IvyPanda. (2019, June 12). Implementation of Total Quality Management (TQM): Toyota Case Study. https://ivypanda.com/essays/total-quality-management-tqm-implementation-toyota/

"Implementation of Total Quality Management (TQM): Toyota Case Study." IvyPanda , 12 June 2019, ivypanda.com/essays/total-quality-management-tqm-implementation-toyota/.

IvyPanda . (2019) 'Implementation of Total Quality Management (TQM): Toyota Case Study'. 12 June.

IvyPanda . 2019. "Implementation of Total Quality Management (TQM): Toyota Case Study." June 12, 2019. https://ivypanda.com/essays/total-quality-management-tqm-implementation-toyota/.

1. IvyPanda . "Implementation of Total Quality Management (TQM): Toyota Case Study." June 12, 2019. https://ivypanda.com/essays/total-quality-management-tqm-implementation-toyota/.

Bibliography

IvyPanda . "Implementation of Total Quality Management (TQM): Toyota Case Study." June 12, 2019. https://ivypanda.com/essays/total-quality-management-tqm-implementation-toyota/.

IvyPanda uses cookies and similar technologies to enhance your experience, enabling functionalities such as:

- Basic site functions

- Ensuring secure, safe transactions

- Secure account login

- Remembering account, browser, and regional preferences

- Remembering privacy and security settings

- Analyzing site traffic and usage

- Personalized search, content, and recommendations

- Displaying relevant, targeted ads on and off IvyPanda

Please refer to IvyPanda's Cookies Policy and Privacy Policy for detailed information.

Certain technologies we use are essential for critical functions such as security and site integrity, account authentication, security and privacy preferences, internal site usage and maintenance data, and ensuring the site operates correctly for browsing and transactions.

Cookies and similar technologies are used to enhance your experience by:

- Remembering general and regional preferences

- Personalizing content, search, recommendations, and offers

Some functions, such as personalized recommendations, account preferences, or localization, may not work correctly without these technologies. For more details, please refer to IvyPanda's Cookies Policy .

To enable personalized advertising (such as interest-based ads), we may share your data with our marketing and advertising partners using cookies and other technologies. These partners may have their own information collected about you. Turning off the personalized advertising setting won't stop you from seeing IvyPanda ads, but it may make the ads you see less relevant or more repetitive.

Personalized advertising may be considered a "sale" or "sharing" of the information under California and other state privacy laws, and you may have the right to opt out. Turning off personalized advertising allows you to exercise your right to opt out. Learn more in IvyPanda's Cookies Policy and Privacy Policy .

- Corpus ID: 73594462

Total Quality Management and Business Excellence: The Best Practices at Toyota Motor Corporation.

- S. Toma , Shinji Naruo

- Published 1 May 2017

- Business, Engineering

- The AMFITEATRU ECONOMIC journal

18 Citations

How to characterize business excellence and determine the relation between business excellence and sustainability, marketing mix and corporate social responsability in automotive industry – case study: mazda motor corporation, lean production system development through leadership practices, avrasya sosyal ve ekonomi araştırmaları dergisi (asead) eurasian journal of researches in social and economics (ejrse), business excellence through the theory of accountability, organizational excellence methodologies (oems): a systematic literature review, modelling and analyzing of critical success factors for implementing uae’s government excellence model in the public sector: an ism and fuzzy-micmac approach, an exploratory study of common issues and key differences between the european foundation for quality management and the united arab emirates public sector excellence model: public sector organisation results, 48 references, the toyota way : 14 management principles from the world's greatest manufacturer.

- Highly Influential

The linkage among management systems, practices and behaviour in successful manufacturing strategy

In search of excellence : lessons from america's best-run companies, best manufacturing practices : what do the best-performing companies do, the genealogy of lean production, the machine that changed the world : the story of lean production, juran on leadership for quality : an executive handbook, best manufacturing practices and their linkage to top‐performing companies in the us furniture industry, manufacturing best practice and performance studies: a critique, development and validation of tqm implementation constructs, related papers.

Showing 1 through 3 of 0 Related Papers

Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

Download Free PDF

Total Quality Management: Analyzing and criticizing of the practices used in Toyota

Related papers

International Business Research, 2009

This study came to examine the impact of Total Quality management (TQM) as instrument in achieving on the organisational performance. TQM is defined as a policy that essentially aimed at establish and deliver high quality products and services that cover all their client's demands and achieve a high level of customer satisfaction. Total Quality Management (TQM) is a management is an administrative approach for firms focused on quality, in light of the cooperation and every individuals and aims at long haul accomplishment through consumer's loyalty and advantages to all individuals from the associations and society. The impact of many organisations failure to properly implement TQM by all administration level, challenges the organisation ability to organise frequent employee training have been a big problem. This research work attempt to find out the effect of TQM execution in the board inclusion, challenges disturbing the usages, impact of employee training and TQM standard application to the accomplishment of organisational goal. The key discoveries demonstrated that rehearsing TQM but it is yet to implement it to the highest level of subscribing to a quality reward system. The implementation of TQM is at the quality assurance level. It was discovered that administration inactions undermined initiative promise to quality and rendered TQM rehearsal insufficient. It is through questionnaires method and oral interview that data are collected from the aforementioned organisations. References were made to journals, related books, internet the aforementioned organization concurred that TQM have in hierarchical execution.

Computers & Industrial Engineering, 1990

This paper attempts to identify the TQM practices in two different sectors and examines the difference between them by analyzing their commonalities with respect to their implementation as applicable to both the sectors. The methodology adopted was critically examining the literature on TQM practices followed by manufacturing and service sectors.

World globalization is a key factor for the increase of market competition through companies that are continuously improving their innovation, productivity as well as cost optimization. This is achieved through the constant development of innovative ideas and involving every employee in the process of change within the company. In order to meet increasingly more demanding customers, companies need to implement quality improvement in every phase of their internal processes. This paper analyses the application of the quality system currently in place within a Macedonian Air Conditioning Company and aims to create and implement a Total Quality Management (TQM) system on the basis of that research. By successfully implementing the new TQM philosophy, all of the companies’ internal processes and employees work toward process improvement, quality assurance as well as meeting the demands and wishes of all parties involved. The TQM system also plays a huge factor in improving customer loyal...

International Journal of Online and Biomedical Engineering (iJOE)

The study intended to investigate the factors that affect the total quality management (TQM) process in the 1,800 firm Thai auto parts industry. Automotive parts export shipments from Thailand are ranked 13th globally and are destined for over 100 countries, with Thailand’s combined automotive industry representing 12% of GDP. Therefore, with the authors understanding the importance of this economic sector, a research tool was developed, which contained a five-level scale to investigate 455 auto parts managers, executives, and owners’ opinions. Topics surveyed included the respondents’ opinions on the effects of knowledge management (KNG), product quality (QLY), strategic planning (STY), and technology and innovation (TIN) on the Thai auto part industry TQM process. The study’s eight hypotheses made use LISREL 9.1 software to analyze the final structural equation model (SEM). Results showed that all the model's variables had a positive influence on TQM, which can be combined to ...

The Malaysian Administrative Modernization and Management Planning Unit (MAMPU) has outlined Total Quality Management (TQM) by means of seven core principles: (1) top management commitment, (2) strategic quality planning, (3) customer focus, (4) training and recognition, (5) enhancing teamwork, (6) performance measurement, and (7) quality assurance. Malaysian organizations are encouraged to apply these core principles in order to attain competitive advantage in the marketplace. The present study has made an attempt to survey the level of awareness and implementation of these principles in a typical Malaysian organization. The data has been collected through a questionnaire survey and interviews. Seventy two of the total of 125 employees of the organization participated in the survey. Details of the findings are discussed and implications are highlighted.

Jurnal Aplikasi Bisnis dan Manajemen, 2021

Loading Preview

Sorry, preview is currently unavailable. You can download the paper by clicking the button above.

Proceedings of the 2011 InSITE Conference, 2011

SSRN Electronic Journal, 2014

Proceedings on Engineering Sciences, 2022

International Journal of Intellectual Human Resource Management (IJIHRM)

Journal of Economics, Business, and Accountancy | Ventura, 2011

Asian Journal of Engineering and Applied Technology, 2018

Kuwait Chapter of Arabian Journal of Business and Management Review, 2013

Global Journal of Business, Economics and Management, 2017

International Journal of Scientific & Engineering Research, 2016

Quality and Quantity, 2006

Eurasian Journal of Higher Education, 2021

Related topics

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

U.S. Embassy & Consulates in Russia

Social / search.

Yekaterinburg & Sverdlovsk Oblast

History, Politics, and Economics

Yekaterinburg lies at the crossroads between Europe and Asia, east of the slopes of the Ural Mountains in central Russia. The continental divide is 30 kilometers west of the city. Yekaterinburg is Russia’s third or fourth largest city with a population of 1.5 million. It was founded in 1723 and is named for Peter the Great’s wife, Catherine I. Peter recognized the importance of Yekaterinburg and the surrounding region for the rapid industrial development necessary to bolster Russia’s military power.Today, Yekaterinburg is primarily known both as a center of heavy industry and steel-making, the Russian equivalent of Pittsburgh, and as a major freight transportation hub. Its major industries include ferrous and non-ferrous metallurgy, chemicals, timber, and pulp and paper. Yekaterinburg has long been an important trading center for goods coming from Siberia, Central Asia and Europe. The city also has a reputation as a center of higher education and research. The Urals Branch of the Russian Academy of Sciences is located there with its 18 institutes and numerous research facilities linked to industry. Yekaterinburg is also well known as a center for the performing arts. Its Opera and Ballet Theater dates back to 1912. The Urals Philharmonic Orchestra is the largest symphony orchestra in central Russia.

Yekaterinburg is the capital of Sverdlovsk Oblast (an oblast is the equivalent of a American state). Economically, Sverdlovsk is among 10 of the 89 administrative subdivisions of the Russian Federation that are net contributors to the federal budget. Sverdlovsk has produced many prominent political figures, including Russia’s first President, Boris Yeltsin, and Russia’s first elected Governor, Eduard Rossel. Since the establishment of the Russian Federation, Sverdlovsk Oblast has been one of the nation’s leaders in political and economic reform. In 1996, Sverdlovsk became the first oblast to conclude agreements with the Federal Government granting it greater political autonomy and the right to conduct its own foreign economic relations.

Economic reform has gathered momentum in Sverdlovsk Oblast. The majority of Sverdlovsk’s industries have been privatized. 75% of enterprises are at least partially owned by private interests. About three-quarters of retail sales and industrial output is generated by private enterprise. Services have grown to 40 percent of oblast GDP, up from only 16 percent in 1992. About 25,000 small businesses are registered in the oblast. Small businesses make up about one-third of the construction, trade and food service.

Industry and Natural Resources

Sverdlovvsk Oblast, like most of the Urals region, possesses abundant natural resources. It is one of Russia’s leaders in mineral extraction. Sverdlovsk produces 70% of Russia’s bauxite, 60% of asbestos, 23% of iron, 97% of vanadium, 6% of copper and 2% of nickel. Forests cover 65% of the oblast. It also produces 6% of Russia’s timber and 7% of its plywood. Sverdlovsk has the largest GDP of any oblast in the Urals. The oblast’s major exports include steel (20% of its foreign trade turnover), chemicals (11%), copper (11%), aluminum (8%) and titanium (3%). In terms of industrial output, Sverdlovsk ranks second only to Moscow Oblast and produces 5% of Russia’s total. Ferrous metallurgy and machine-building still constitute a major part of the oblast’s economy. Yekaterinburg is well known for its concentration of industrial manufacturing plants. The city’s largest factories produce oil extraction equipment, tubes and pipes, steel rollers, steam turbines and manufacturing equipment for other factories.

Non-ferrous metallurgy remains a growth sector. The Verkhnaya Salda Titanium Plant (VSMPO) is the largest titanium works in Russia and the second largest in the world. A second growth sector is food production and processing, with many firms purchasing foreign equipment to upgrade production. The financial crisis has increased demand for domestically produced foodstuffs, as consumers can no longer afford more expensive imported products. Many of Yekaterinburg’s leading food processors — including the Konfi Chocolate Factory, Myasomoltorg Ice-Cream Plant, Myasokombinat Meat Packing Plant and Patra Brewery — have remained financially stable and look forward to growth.

Foreign Trade and Investment

Sverdlovsk Oblast offers investors opportunities mainly in raw materials (metals and minerals) and heavy industries (oil extraction and pipeline equipment). There is also interest in importing Western products in the fields of telecommunications, food processing, safety and security systems, and medicine and construction materials. Both Sverdlovsk Oblast and Yekaterinburg city officials have encouraged foreign investment and created a receptive business climate. The oblast has a Foreign Investment Support Department and a website which profiles over 200 local companies. The city government opened its own investment support center in 1998 to assist foreign companies. Despite local efforts, foreign investors face the same problems in Yekaterinburg as they do elsewhere in Russia. Customs and tax issues top the list of problem areas.

Sverdlovsk Oblast leads the Urals in attracting foreign investment The top five foreign investors are the U.S., UK, Germany, China and Cyprus. About 70 foreign firms have opened representative offices in Yekaterinburg, including DHL, Ford, IBM, Proctor and Gamble, and Siemens. Lufthansa airlines has opened a station in Yekaterinburg and offers three flights per week to Frankfurt.

America is Sverdlovsk’s number one investor with $114 million in investment and 79 joint ventures. The three largest U.S. investors are Coca-Cola, Pepsi and USWest. Coca-Cola and Pepsi both opened bottling plants in Yekaterinburg in 1998. USWest has a joint venture, Uralwestcom, which is one of Yekaterinburg’s leading companies in cellular phone sales and service. America is Sverdlovsk Oblast’s number one trading partner. In 1998, Boeing signed a ten-year titanium supply contract valued at approximately $200 million with the VSMPO titanium plant. Besides the U.S., Sverdlovsk’s top trading partners include Holland, Kazakhstan, Germany and the UK.

Yekaterinburg, like most of Russia, has a continental climate. The city is located at the source of the Iset River and is surrounded by lakes and hills. Temperatures tend to be mild in summer and severe in winter. The average temperature in January is -15.5C (4F), but occasionally reaches -40C (-40F). The average temperature in July is 17.5C (64F), but occasionally reaches 40C (104F). Current weather in Yekaterinburg from http://www.gismeteo.ru/ .

- Sverdlovsk Oblast Map

- Yekaterinburg Map

Footer Disclaimer This is the official website of the U.S. Embassy & Consulates in Russia. External links to other Internet sites should not be construed as an endorsement of the views or privacy policies contained therein.

Bank Mines, Yekaterinburg , Sverdlovsk Oblast , Russia i Regional Level Types Bank Mines Group of Mines Yekaterinburg City Sverdlovsk Oblast Oblast Russia Country function showexplain() { $("#locexplain").toggle(); if (typeof movemap === "function") movemap(); }

Select mineral list type, mineral list.

ⓘ Brochantite

Detailed Mineral List:

| Cu (SO )(OH) |

List of minerals arranged by Strunz 10th Edition classification

| 7.BB.25 | Cu (SO )(OH) | ||

List of minerals for each chemical element

| H | ||

|---|---|---|

| H | Cu (SO )(OH) | |

| O | ||

| O | Cu (SO )(OH) | |

| S | ||

| S | Cu (SO )(OH) | |

| Cu | ||

| Cu | Cu (SO )(OH) | |

Other Regions, Features and Areas containing this locality

- Ural Volcanic Arcs Volcanic Arc

- Middle Urals Mountain Range

- ⭔ Western Siberian basin (Zapadno-Sibirskiy basin) Economic Region

- Second League, Division B, Group 4 , Round 14

Akron-2 Togliatti vs Ural 2 Ekaterinburg live score, H2H results, standings and prediction

Who will win.

- Find out who scored in a live match

- Get real-time information on which team is dominating the match using the Attack Momentum

- Follow detailed statistics such as ball possession, shots, corner kicks, big chances created, cards, key passes, duels and more

- Check all head to head matches – for instance, in the last season Akron-2 Togliatti and Ural 2 Ekaterinburg played 2 games against each other

- Track all home and away games for each team in the Second League, Division B, Group 4

- Check out how Sofascore community votes on which team is more likely to win this match.

IMAGES

VIDEO

COMMENTS

The Toyota Corporation case study report is based on the implementation of total quality management (TQM) meant to improve the overall performance and operations of this automobile company. TQM involves the application of quality management standards to all elements of the business. Get a custom report on Implementation of Total Quality ...

The Toyota Way Model was introduced). 12. Implementation of TQM in Automotive Industry: o Internally, there are four fields of quality management in the Automotive industry: • Sales - directly ...

T oyota Quality System case study. Introduction. T oyota from the early 1960s alongside their supplier network consolidated the way in which. they were able to refine their production system ...

Based on the corporate philosophy of 'customer first' and 'quality first' since its founding, Toyota Motor Co., Ltd. won the Deming Application Prize in 1965 and the Japan Quality Control Award in 1970, following the introduction of statistical quality control (SQC) in 1949, and has conducted Total Quality Management (TQM) based on the unchanging principles of 'customer first', kaizen ...

The paper aims to highlight the relationship between the concepts of total quality management and business excellence, and to identify and analyze the best practices related to them at Toyota Motor Corporation, a leader of automotive industry. The information obtained through the direct and personal observation method and from multiple ...

Various materials concerning Toyota Motor Corporations' management and company information. 75-Year History TOP > A 75-Year History through Data > Management and Company Information ... Total Quality Management (TQM) Changes and Innovations; Organizational Changes; Executives.

Corpus ID: 73594462; Total Quality Management and Business Excellence: The Best Practices at Toyota Motor Corporation. @article{Toma2017TotalQM, title={Total Quality Management and Business Excellence: The Best Practices at Toyota Motor Corporation.}, author={Sorin George Toma and Shinji Naruo}, journal={The AMFITEATRU ECONOMIC journal}, year={2017}, volume={19}, pages={566-580}, url={https ...

Toyota establishes a Quality Function Policy each year based on the policy for 2018. In 2018, we have identified focal activities and are working on various issues based on the policy of "Establish a solid foundation by adhering rigidly to the work basics and build competitive quality from the customer's viewpoint.".

To start, Toyota Motor Co., Ltd. worked to deploy quality control education, led by the Quality Control Division, launching a campaign to halve product defects, and, on the manufacturing front line study sessions were held mostly for the various workplace supervisors (the plant general manager and group managers) to address workplace problems.

Total Quality Management is a concept applied in the automobile industry, including the Toyota Corporation. It focuses on continuous improvement across all branches and levels of an organization. Through TQM, Toyota Corporation has been able to create value, which eventually leads to operation efficiencies. These efficiencies have particularly ...

1 Implementation of TQM in Automotive Industry Case Study: Toyota Motor Corporation J Component - Total Quality Management - MAT3010 Reba Gayathri Jesudoss 19MIY0020

The main results show that the best practices of Toyota Motor Corporation related to total quality management and business excellence derive from the Toyota Production System and these practices ...

Consideration of Total Quality Management philosophy and its implications, I would like to choose the Toyota Motor Corporation (TMC) for this study. Considering the development of total quality management in Japan, the studies about quality of American specialists should show regard to that they developed a new approach to quality management.

Sverdlovvsk Oblast, like most of the Urals region, possesses abundant natural resources. It is one of Russia's leaders in mineral extraction. Sverdlovsk produces 70% of Russia's bauxite, 60% of asbestos, 23% of iron, 97% of vanadium, 6% of copper and 2% of nickel. Forests cover 65% of the oblast. It also produces 6% of Russia's timber and ...

Bank Mines, Yekaterinburg, Sverdlovsk Oblast, Russia : Estimate based on other nearby localities or region boundaries.

About the match. Fakel Voronezh is going head to head with Ural Yekaterinburg starting on 12 May 2024 at 13:30 UTC at Tsentralnyi Profsoyuz Stadium stadium, Voronezh city, Russia. The match is a part of the Premier League. Fakel Voronezh played against Ural Yekaterinburg in 2 matches this season. Currently, Fakel Voronezh rank 11th, while Ural ...

Akron-2 Togliatti is going head to head with Ural 2 Ekaterinburg starting on 28 Jul 2024 at 12:00 UTC . The match is a part of the Second League, Division B, Group 4. Akron-2 Togliatti played against Ural 2 Ekaterinburg in 2 matches this season. Currently, Akron-2 Togliatti rank 13th, while Ural 2 Ekaterinburg hold 5th position.